Up to 70% of the costs in organic vegetable production are labor costs.

After harvesting and marketing, weed control forms the second largest share of labor costs. Due to the slow growth of vegetable crops, weeding must be done as early as possible and very regularly, otherwise crops will quickly become overgrown. Generally, cultivation equipment such as harrows can remove weeds between planting rows.

However, vegetable crops - especially in the very early stages - are often too fragile or difficult to maintain with machinery due to mixed crops. For these reasons, vegetable growers often still have to weed by hand with a classic hoe. Due to the high share of fresh vegetables in total sales and the essentially regional distribution structure, monoculture landscapes such as those for cereals, corn, canola and soybeans are rare and small, specialized farms predominate. The significantly better yield situation compared to conventional farms has led to a strong increase in organic vegetable production in recent years. The focus is on seasonal fresh vegetables such as lettuce, spring onions or radishes, which offer the highest yield potential. Up to four harvests of different vegetables are possible per growing year and bed, grown in a sophisticated crop rotation with up to 50 vegetable varieties. For this reason, vegetable cultivation offers the ideal basis for a transition to an organic farm, e.g. through successive partial conversions.

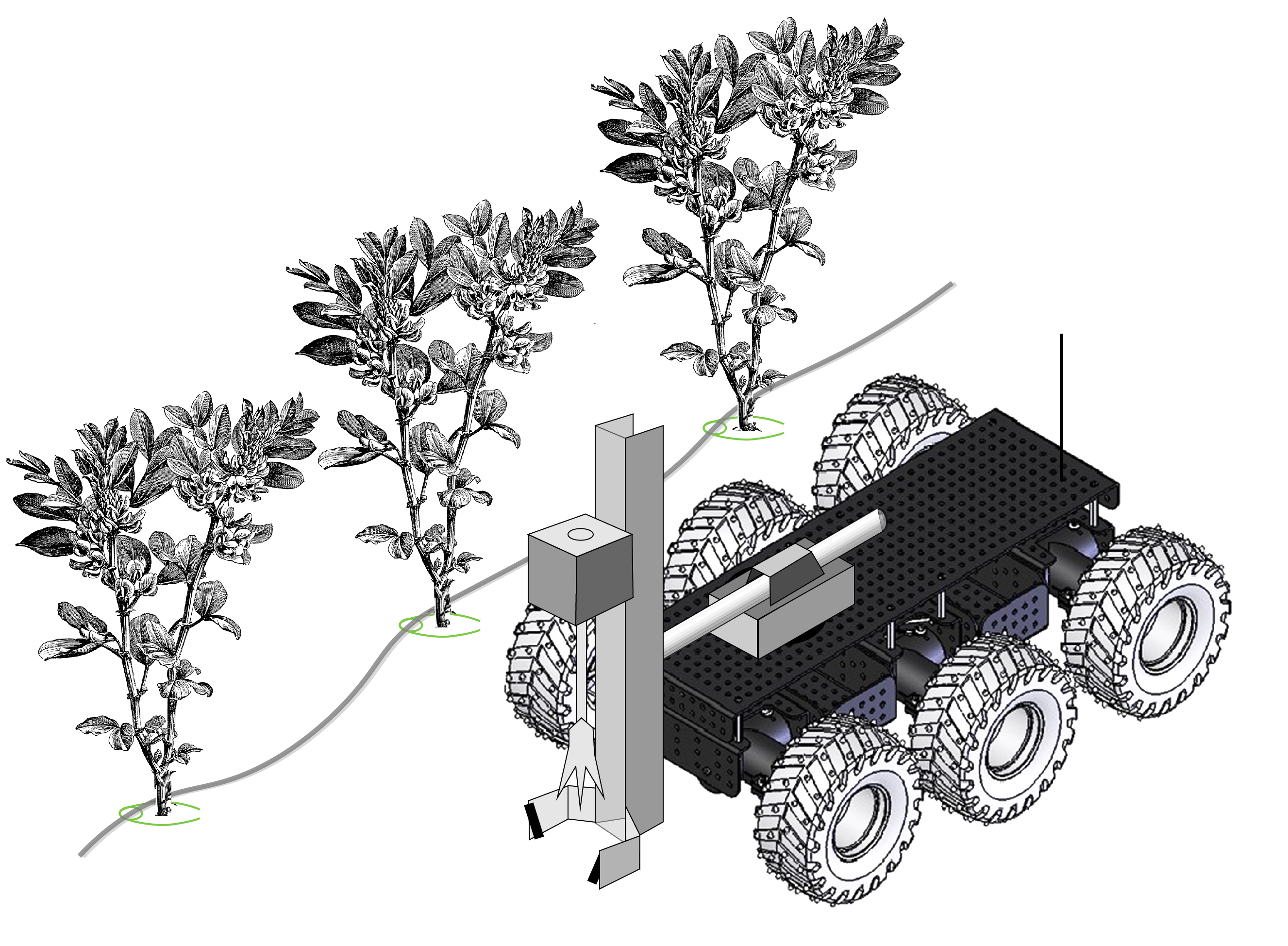

The core of the novel approach is the patent-pending marking of crop zones during planting or sowing. This avoids the need for complex image-based crop identification procedures and allows crops to be reliably identified even in distinct mixed crops and regardless of the crop type. The small MRV-10 robot designed by biogriculture is the first component of robots with interchangeable tools for soil cultivation and crop management that can be combined to form a swarm. Here, the individual locations in the swarm are tracked via GPS and can also be monitored and controlled via a mobile terminal. Due to its small size and a weight of only a few kilograms, the MRV-10 is suitable for cultivating narrow row spacing without additional tracks, can adapt to changing row spacing with the help of a rotating and extendable arm, and prevents soil compaction.

Instead of costly training of the MRV-10 for selection via specific crop characteristics, the method presented enables it to reliably distinguish crops from weeds without specific information about the crops in question.

In the first working prototype, crop zone detection is performed using induction detectors developed for the metalworking industry. These are certified for use in wet areas and have been field-tested many times. An integrated GPS is used to define the working area, coordinate the swarm and autonomously track movement along the crop rows.